Injection Mould Tooling UK

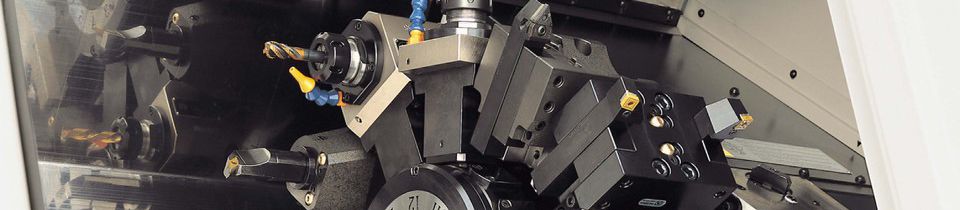

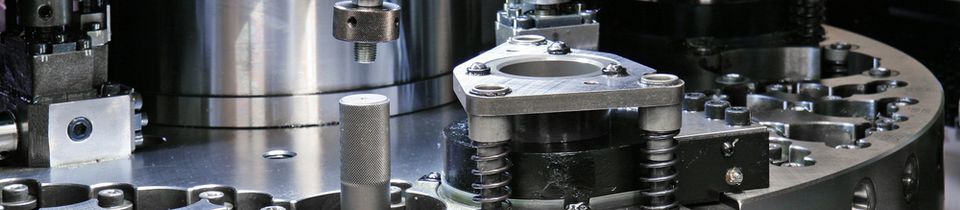

The ATS Toolroom is a modern well equipped tool manufacturing facility with a complete range of the latest CNC machinery, Utilising this equipment our highly skilled toolmakers and specialist machinists manufacture high quality Injection Mould tooling for the Medical, Packaging, Automotive & Domestic Appliance sectors.

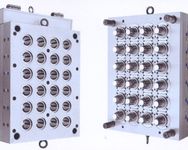

Generally specialising in the more technical types of tooling ATS has a wealth of experience in Multi-Cavity fast cycling tools, 2-Shot technology and large multi-movement tooling up-to 9000kgs most incorporating multi-drop and sequential valve gate hot runner systems.

All Tooling is designed in-house by our own Tool Design Engineers in 3-D using the latest Unigraphics CAD software, Moldflow is carried out where appropriate along with full component design feasibility studies so as to capture any potential issues at the Design stage, tool design data is then up-loaded onto our main server and our Toolroom personnel use Delcam Powermill & Powershape to manufacture & inspect mould parts ready for final assembly by our Toolmakers.

Having our own moulding facility on-site enables us to sample and mature tools prior to final delivery, setting sheets are provided with each tool along with a full Tooling manual including 2-D & 3-D CAD data, Certificates of Conformity for steel & heat treatment processes, Core & Cavity dimensional results and Hot Runner system information.

Customers are more than welcome to attend each mould trial and can bring their own Process Engineers or instruct ours to ensure that the tool setting conditions replicate as closely as possible their own.